Precision BioMEMS

A Microfabrication Facility for Medical Devices

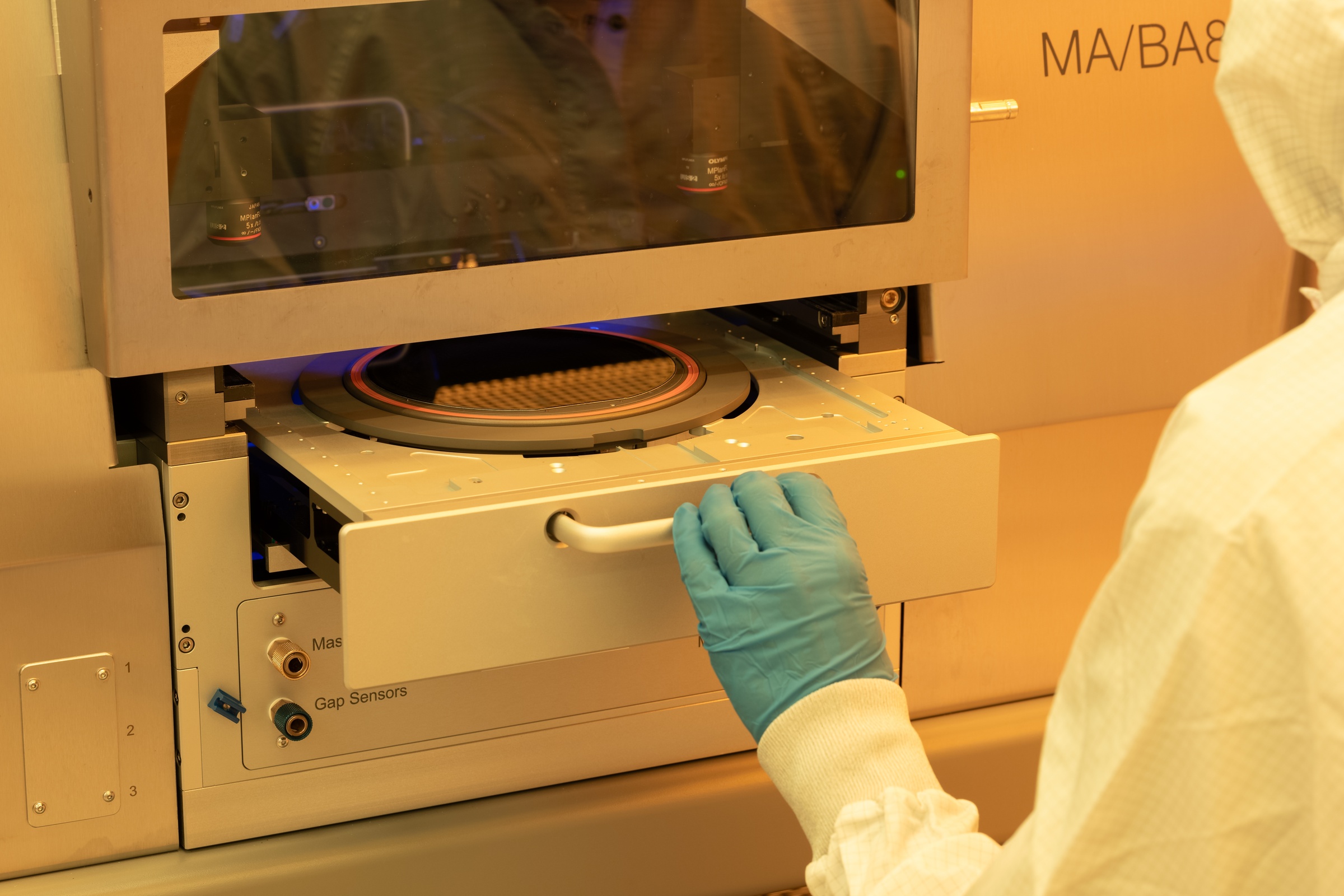

Precision BioMEMS, a wholly owned subsidiary of Precision Neuroscience, operates a 22,000 square foot micro-electrical mechanical systems (MEMS) fabrication facility that produces our high-quality biocompatible microelectrode arrays and offers foundry services to pioneering third-party companies. Located in Addison, Texas, the facility includes an ISO class 5 cleanroom that is equipped with a range of advanced fabrication tools, with a focus on biocompatible processes and materials.

In-House Manufacturing

Precision uses photolithography and other MEMS manufacturing techniques to pattern our 1,000+ channel polyimide-based neural implants. Performing this specialized manufacturing in-house allows Precision to control the production and quality of the most critical component of our system, while allowing for rapid development of new technologies.

Foundry Services

Precision BioMEMS works with groundbreaking companies in fields such as medical diagnostics and advanced micro mechanical sensing to address complex problems. Our technicians and engineers collectively have decades of experience in MEMS, both for R&D projects and high quality production, and are continually exploring the most cutting-edge processing methods. Together with our partners, we are pushing medical device manufacturing into the future.

Over 50 Tools Spanning Broad Capabilities

The Future of Medical MEMS

Contact Us

To learn more about our foundry services, fill out the form below or email us directly at sales@precisionbiomems.io

Your message has been submitted

We’ll get back to you as soon as possible.